BioMassters: A Tailored Approach with Vast Potential

Established in 2020, BioMassters Ltd. is a Rwandan company that produces pellet fuel out of biomass waste and supplies modern pellet stoves. BioMassters aims to provide an affordable, user-friendly, low-carbon cooking solution that is uniquely tailored to customers in urban Rwanda and beyond, while building a profitable, sustainable business.

Claudia Muench, CEO of BioMassters, spoke with the Clean Cooking Alliance about the company’s customer-driven approach and the valuable lessons that she and her team learned from working at Inyenyeri.

This interview is part of a series of conversations CCA is having with business leaders across the clean cooking sector.

Clean Cooking Alliance (CCA): Can you tell us about BioMassters’ products and services?

Claudia Muench (Muench): BioMassters is a Rwandan energy company that offers modern, clean, and affordable cooking solutions. We use local biomass waste to manufacture and sell cooking fuel in the form of wood pellets to households and small businesses. These customers also purchase a highly efficient and clean cookstove from us, either outright or through consumer financing. Customers thus save money in two ways: not only is a kilogram of pellets cheaper than an equivalent amount of charcoal, but the pellet-and-stove combination burns more efficiently compared to charcoal, so fewer pellets are needed overall.

CCA: What are the defining characteristics of your customer base?

Muench: Our customers are typically urban and peri-urban families who have been using charcoal to cook. Our products work for homes with low purchasing power, but we are also finding that our solution is well liked by more affluent families, too. For instance, in light of soaring energy prices, many Rwandans cooking with gas also want to sign up for pellet cooking solutions, which are comparable in convenience and cleanliness and come at a far lower price.

CCA: What motivated you to start BioMassters?

Muench: While working in finance in the UK for a large logistics company, I got close to engineering projects, understanding processes and cost saving opportunities. I also generally enjoyed looking behind and beyond the numbers. At the same time, I always had the desire to work on projects that impact the lives of people less fortunate than myself. In 2019, I started as the CFO of Inyenyeri, a company that had a clear purpose: to bring truly clean and advanced cookstoves to the poorest people and impact their health, their pockets, their cooking experience, and the environment. For two years now, I have run my own business in pellet-based cooking that I started with five co-founders. All the founders of BioMassters were also part of Inyenyeri.

CCA: After Inyenyeri’s closure, how did you decide what to do next?

Muench: The current BioMassters team received such overwhelming encouragement from former customers, government officials, and other stakeholders that we got together to evaluate why Inyenyeri couldn’t have continued and what could have been done differently. Once we saw how to make Inyenyeri’s business model commercially viable and sustainable, it was clear we had to give it a go. We also believe that, with catastrophic climate change on the way, we need bold action and willingness to take risks. The end of Inyenyeri should be treated as an unfortunate step in a very important learning process; without it, we would not have created BioMassters.

CCA: What is different with the business model that BioMassters is now rolling out?

Muench: We’re very focused on commercializing the business and targeting urban and peri-urban cash-paying customers (and no longer targeting rural, cashless households, as Inyenyeri did). We also looked at the way we source biomass and partnered with the largest forest management company in Rwanda, using their sawmill and forestry waste to make our pellets. Further, we are extremely lean in our operational cost structure. We are headquartered in Kigali, without overhead in the global north. A more practical example is that all our customer transactions are mobile money transactions or bank transfers. We don’t accept cash. Furthermore, we have a few agents doing cooking demonstrations and door-to-door outreach, but generally we spend very little on marketing because ours is not a push product; it genuinely solves a problem for the customer.

We aim to prove that the business can scale and be profitable. We already know the costs of raw materials, electricity, labor, bagging, and consumables, among other things. We also have a good sense of the market price for pellets. A recent financial feasibility study, conducted by a third party and made possible with support from CCA, suggests that our plans for a modern pellet factory in Rwanda are viable.

CCA: What makes your company unique from others in the clean cooking ecosystem?

Muench: To create sustained adoption of a modern, low-carbon cooking solution, we need to provide both a better stove and a better fuel than what households currently use (i.e., charcoal). It is really the combination of the “tool and fuel” that leads to such a drastically improved cooking experience that customers choose to stick to it.

This is also where the business opportunity lies. Our stoves only need to be purchased every 3-5 years, but fuel gets purchased every day, week, or month. Urban and peri-urban households spend, in total, a lot more money on fuel than on stoves. If you can provide a cheaper fuel that is still modern and low carbon, then you are truly creating value.

We provide one of the few modern and low-carbon solutions that makes use of biomass as a source of cooking energy. We believe that densifying biomass into pellets and burning them in an advanced gasification stove holds the most promise for the foreseeable future. By “the most promise” I mean a truly clean and durable stove that is convenient to cook on, is purchased at an affordable price, and uses low-carbon, low-cost, locally sourced fuel. This is partially because biomass is locally available, and the process shortens supply chains and creates jobs. It’s also partially because the fuel can be produced at a low cost, making it an affordable option for customers. Besides, if we take replanting seriously, biomass can be an indefinite source of renewable energy.

CCA: Can you tell us more about the climate benefits of your approach?

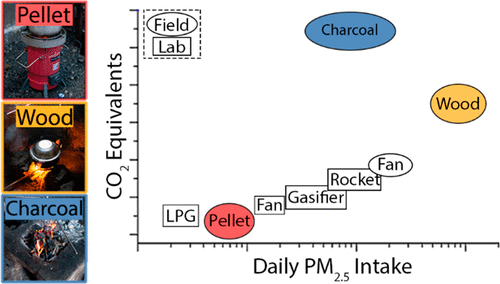

Muench: During the Inyenyeri years, it was demonstrated that pellet cooking provides enormously positive impacts in terms of the environment, climate, health, and affordability. Our solution needs 90 percent less biomass compared to charcoal, and it’s the only form of advanced biomass cooking that meets the World Health Organization’s criteria for “clean for PM2.5 emissions” (ISO Tier 4 and above for that metric). Emissions levels from pellets are approaching that of LPG (see chart). Tier 4 is the second-best ISO classification out of 5 tiers.

Source: Champion and Wyatt, 2019

CCA: What excites you about the Rwandan clean cooking market, and why is it the right place for BioMassters to operate?

Muench: As a deeply landlocked country, Rwanda is particularly well suited to promote a homegrown modern energy solution. Moreover, despite the country’s tremendous progress over the past few decades, many households are still very price sensitive due to low incomes. BioMassters’ products are such a good market fit. The cooking experience is far superior to the charcoal that most people use today, and there’s not much unlearning and relearning required by household cooks. I personally also cook with pellets every day, and I really like it.

Additionally, the ease of doing business in Rwanda is high as it offers a very well-structured bureaucracy where most things can now be done online and where the rules are clear and applied consistently for everyone across the board. Most importantly, Rwanda benefits from a very clear vision of where the country is headed, with very ambitious energy targets to reduce biomass use by half by 2024 compared to 2017 levels.

CCA: How do you see your business and the clean cooking sector developing over the next 5-10 years?

Muench: I see a bright future for modern, low-carbon cooking solutions like ours. I believe there are very few commercial, private sector interventions in the world that can avoid so much carbon at such little cost, while giving a return to investors and having so many benefits to the environment, biodiversity, energy security, health, gender, economic well-being, and more.

With the worsening climate crisis, and global efforts such as the SDGs by 2030 and the 2050 “net zero” target coming from the Paris Agreement, there will undoubtedly be an influx of much larger capital into viable businesses in the clean cooking sector. The experiences of companies like KOKO Networks, Circle Gas, and BURN Manufacturing are already demonstrating how much interest is growing in clean cooking as a destination for carbon financing.

Moreover, there are strong, long-term trends that support the growing need and opportunity for homegrown, modern energy solutions like ours. With Africa’s rapid population growth and urbanization, pressure on the remaining forests and other natural resources will continue to increase. By the end of the century, half of the 10 most populous countries in the world will be in Africa. Where will all the urban and peri-urban households get their cooking energy from?

To preserve a habitable and independent continent, I think that policies and investments will eventually help to accelerate solutions that do not rely on fossil fuels or global supply chains. The world has known for a while that it has to get rid of its fossil fuel addiction, and the war in Ukraine and the European dependency on Russian gas are only accelerating this realization. At BioMassters, we believe global and local inflation of energy prices will continue driving consumers and investors to our kind of solution.

Within the next 5-10 years, I hope that BioMassters will have helped to establish modern pellet manufacturing technology in Africa and scale the industry by running several factories in multiple countries. We already export pellets to Kenya and the Democratic Republic of Congo. Based on our knowledge of the cost structures of mature pellet manufacturing industries in Europe, North America, and Asia, we believe we can provide a truly affordable energy solution in Africa.

Lastly, I’m convinced that a lot more research and development will go into stove innovation in the coming years. After all, it is users’ experience and behaviors that will ultimately drive market opportunities and business development, and there is still a lot of room for improvement. Fortunately, we can expect to see innovation that improves the user experience, further improves fuel combustion and efficiency, and enables remote monitoring through “internet of things” technology. We will also see innovation that increases the use of local materials, local labor, and local assembly or production processes to drive down costs without compromising on performance. As investments in the sector grow, costs will come down, too, as has been seen in the solar sector over the past decade or two. It is about time that cooking companies attracted similar amounts of capital so that it can finally fulfill its enormous potential.